Summary of Steps to Resolve Issues When the Display Screen Won’t Turn On

Step 1:

Provide the schematic diagram and testing program. Generally, 95% of customers can light up the display screen with the information.

Step 2:

If the display still doesn’t turn on, the customer needs to determine whether the issue lies in the hardware or software. At this point, it’s best to provide the customer with a demo unit. This helps the customer confirm that the display itself is not damaged and significantly aids their troubleshooting process.

Step 3:

If the issue persists, the customer can share their schematic design and software with the factory engineers for review to identify any potential problems. This step should resolve 99% of issues.

Step 4:

If the display still doesn’t turn on after the previous steps, the customer can send their designed board to the factory engineers for further troubleshooting assistance.

Note: Some customers send us the MCU or evaluation kit (e.g., development board) they are using and ask us to provide design suggestions. However, this is highly challenging. The market has a vast variety of MCUs, and it is unrealistic for or engineers to be familiar with all of them.

For example, it’s similar to a scenario where our engineers are skilled at repairing Toyota cars, but a customer brings in a Tesla and asks for diagnostics. The engineers would need to spend a significant amount of time studying and understanding the new system.

Here is a detailed description of the issue:

We often receive customer emails like this:

“I have issues with getting the display to work. How can I do?”

When it comes to troubleshooting display screens that won’t turn on, the problem typically falls into two categories: hardware or software.

Hardware:

Configuration Issues

LCD screens often have many pins, and factories may have implemented specific configurations. Simply relying on the datasheet to troubleshoot can sometimes be very challenging. Customers not only need to be familiar with the LCD driver but also deal with component configurations or failures, which can sometimes drive them to frustration.

Proper documentation and detailed schematics are crucial for helping customers overcome these hardware challenges.

Since our engineers already successfully lit up the display, the simplest solution is to provide the schematic diagram of the our testing setup for the display to the customer. This makes the our approach to configuring the display and components clear at a glance.

While the customer’s MCU might differ from the one used by the factory in testing, they are often similar in functionality. Sharing this schematic helps the customer avoid unnecessary detours during troubleshooting.

The schematic typically looks like this:

When Everything Seems Correct, But the Display Still Won’t Light Up:

Sometimes, even when all configurations appear correct, the display still doesn’t turn on. This could be due to common physical issues such as:

- Display damage (e.g., from handling or manufacturing defects).

- FPC (Flexible Printed Circuit) tearing, which disrupts the electrical connection.

- Electrostatic discharge (ESD) damage, which can destroy sensitive components.

For delicate and high-precision displays, it’s recommended to keep at least two spare units on hand to avoid downtime caused by damage.

If the display still doesn’t work, the customer should consider purchasing our demo board or evaluation board. These provide a pre-tested and reliable reference design, significantly shortening the customer’s development cycle and helping them identify whether the issue lies in their setup or the display itself.

Software (Firmware)

For some displays, the configuration can be highly complex, especially with settings like register configurations. These settings often require meticulous understanding and programming, and even factory engineers may occasionally make mistakes.

The good news is that IC manufacturers typically provide example code and library files, which handle the most intricate tasks. By including the library files, engineers can streamline their workflow:

c

Copy code

#include <LibraryFile>

This allows the IC manufacturer’s pre-defined settings to be imported into the program. Afterward, engineers only need to define the interface and desired functions.

For customers unfamiliar with the ICs we use, it’s best to provide the sample code from our product testing. This helps them avoid unnecessary detours and significantly simplifies their development process.

Sample code can be provided in formats such as .txt files, .h (hexadecimal files), or other formats, all of which are useful references for the customer.

Sample code typically looks like this:

Alternatively (when using a compiler IDE)

With the above hardware and software support, 95% of customers can resolve their issues. However, some customers may still be unable to light up the display. This could indicate a problem with the customer’s motherboard.

Supporting the customer’s motherboard is challenging for the factory, mainly because of the vast variety of controllers they use. Factory engineers would need to invest significant time in thoroughly studying the customer’s controller and PCB wiring.

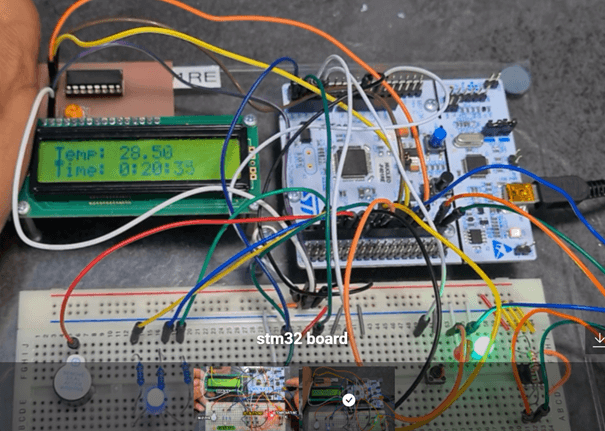

That said, if the factory engineers are familiar with commonly used controllers, such as the 51 series, STM32 series, or Arduino series, they may be able to assist.

If the factory engineers have knowledge of the customer’s MCU, they can provide targeted support by offering:

- The connection method between the MCU and the LCD (as shown in the diagram below).

- Corresponding sample code for the specific setup.

Note:

- Difference Between Demo Board and Evaluation Board (Evaluation Kit):

- Demo Board:

Designed specifically for demonstrating display functionality by the factory. Customers cannot, or find it difficult to, modify the images or display configurations. - Evaluation Board:

More flexible as it allows customers to program and upload their own images, or even modify display settings. Currently, we offer two affordable evaluation boards:- JAZZ-MCU-01:

Designed to drive displays with SPI, I2C, 8-bit, or 16-bit MCU/TTL interfaces. The factory can pre-load images provided by the customer, or if the customer is familiar with AGU’s products, they can upload their own images. - JAZZ-HDMI-01:

Designed to drive displays with RGB, LVDS, or MIPI interfaces. Since it uses HDMI, customers can connect it to a computer to view their desired images and videos directly.

- JAZZ-MCU-01:

- Demo Board:

- Difference Between Software (Code) and Firmware:

- Firmware:

Firmware is also code but is used at the hardware’s lower levels. It typically involves fundamental hardware settings that are rarely changed. For example, in touch control ICs, factory-set firmware often includes settings like touch sensitivity and temperature curves. - Code (Software):

Built on top of the firmware, software enhances the hardware’s functionality by implementing advanced features. It allows for user-specific customization and higher-level operations.

- Firmware: