1. The Concept of E-paper

E-paper can maintain its display even when powered off, possessing a certain memory capacity and most functionalities of traditional paper. The base material of e-paper is primarily polyester compounds, coated with circuits on the surface. Changes in the external electric field control the movement of electronic capsules within the circuit to alter text and images. E-paper features low power consumption and flexibility, providing delicate display quality, a wide viewing angle, and excellent visibility under sunlight without any blind spots.

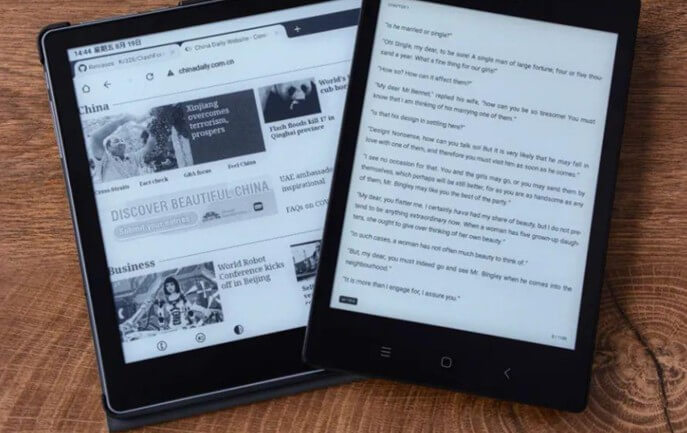

In 1999, E Ink Corporation first introduced a display using electronic ink. In 2007, Amazon released the first-generation Kindle e-reader, equipped with a 6-inch, 4-level e-ink display. From the classic black-and-white e-ink display to today, it has evolved to achieve full-color display capabilities with eight primary colors. Compared to traditional displays, e-ink screens have a bistable characteristic, meaning they only consume power when the pixel colors change. The screen can retain images even after the power is turned off. Moreover, as a display technology, e-ink screens can mimic the visual experience of printing and writing on paper.

2. Display Principles of E-paper

There are several technological approaches for e-paper, including Electrophoretic Display Technology (EPD), Cholesteric Liquid Crystal Display (Ch-LCD), Bistable Twisted Nematic Liquid Crystal Technology (Bi-TNLCD), Electro-Wetting Display Technology (EWD), Electrofluidic Display Technology (EFD), and Interferometric Modulator Technology (iMod). Among these, electrophoretic display technology is the most representative, having been in mass production for many years with mature processes, low cost, high performance, and closest resemblance to traditional paper.

Electrophoretic display technology is one of the earliest developed paper-like display technologies. Its basic principle involves using an external electric field to control the movement of charged particles within a liquid. When these particles move to a specific position, they display different colors.

Electrophoretic ink technology, commonly known as electronic ink, involves applying electronic ink onto a layer of plastic film, then overlaying it with a thin-film transistor (TFT) circuit. Controlled by a driving IC, this arrangement forms pixel graphics, creating Electronic Paper Displays (EPD). Unlike typical flat-panel displays that use light emission to produce images, electronic ink screens primarily employ electrophoretic display technology. They rely on reflecting ambient light for image display, making reading more comfortable. Moreover, the displayed images remain clear even under direct sunlight, with a very wide viewing angle, theoretically up to 180 degrees.

3. Construction of E-paper

Electronic Paper Displays (EPD) typically consist of anti-glare glass, a front light source, touch functionality, electronic ink film, a TFT backplane, a controller, and a power manager, among other components. The electronic ink film is usually composed of millions of microcapsules. These microcapsules contain black and white particles that are charged either positively or negatively. They move in response to changes in the electric field, allowing specific areas to appear black or white, thus forming the corresponding pixel graphics.

The core substance developed by E Ink Holdings for their microcapsule electronic ink technology is electronic ink, which mainly consists of two parts: black dye and white charged titanium dioxide electrophoretic particles.

The electronic particles are suspended in the dye, arranged uniformly and move randomly. They are encapsulated by a transparent shell. Under the influence of an external electric field, the white particles can sense the charge and move in different directions. The side where white particles accumulate can display white, while the opposite side shows the color of the dye, that is, black. E-paper uses this principle to achieve color transitions for text and images.

4. E-paper Materials

- Substrate Materials: E-paper substrates are typically made of plastic (such as polyester film) or glass. Plastic substrates have the advantage of being lightweight and flexible, making them suitable for creating bendable e-paper. Glass substrates, on the other hand, provide better protection and durability.

- Microcapsule Materials: Microcapsules are the core components of e-paper and are usually made of polymer materials. Each microcapsule contains black and white particles, which are typically made from materials such as carbon black or white titanium dioxide. The size of microcapsules generally ranges from a few microns to several tens of microns.

- Conductive Materials: The transparent electrodes of e-paper typically use indium tin oxide (ITO) or other conductive materials. These materials not only possess good conductivity but also high transparency, effectively conducting electricity without affecting the display quality.

- Ink Materials: The pigment particles used in electronic ink are usually made from inorganic or organic materials, offering good dispersibility and stability to ensure the clarity and longevity of displayed images.

- Protective Film: To enhance the durability of e-paper, a protective film is often applied to the surface. This film helps prevent scratches and external damage, thereby extending the lifespan of the e-paper.

5. E-paper Manufacturing Process

The technology of electrophoretic ink, commonly known as electronic ink, is central to the manufacturing process of e-paper. This process involves coating a layer of electronic ink onto a plastic film. A thin-film transistor (TFT) circuit is then laminated onto this coated film. Controlled by a driver IC, this arrangement facilitates the formation of pixel graphics, which are the building blocks of the Electronic Paper Displays (EPD). This method allows for precise control and manipulation of the ink particles within the microcapsules, enabling the display to show images and text by rearranging these particles under electrical influence.

To control production costs and considering the characteristics of electrophoretic display materials, current microcapsule electrophoretic display films are produced using a roll-to-roll coating method. This process allows for the rapid production of display materials that meet the requirements of product applications. The mentioned image would typically show the roll of film material as it is processed in this continuous manufacturing method.

6. Advantages and Disadvantages of E-paper

· Advantages

-

- Low Energy Consumption: E-paper consumes very low power, typically only using electricity when refreshing the display, thus using almost no power in standby mode.

- Good Readability: Due to its reflective display nature, e-paper maintains good readability under strong light, similar to that of traditional paper.

- Lightweight and Flexible: The lightness and flexibility of e-paper make it suitable for various portable devices and flexible displays.

- Eye Comfort: E-paper reduces glare and blue light radiation, making it more comfortable for long reading sessions.

· Disadvantages

-

- Cost: The production cost of e-paper is relatively high, which limits its proliferation in some low-end markets. However, the yield of electrophoretic display technology, especially microcapsule display technology, is expected to improve annually due to its simple manufacturing process and roll-to-roll coating method similar to paper production. As production volumes and yields increase, the cost of e-paper displays is expected to decrease annually. Like other electronics, the price of e-paper displays will likely continue to fall, leading to various emerging applications as costs decrease.

- Slow Refresh Rate: E-paper has a relatively slow refresh rate, making it unsuitable for displaying dynamic videos or rapidly changing content. To meet the performance requirements of bistability, e-paper display technology sacrifices response speed, with update times taking several hundred milliseconds, which is insufficient for video applications. With technological advancements, faster responding e-paper materials have emerged, and response times have been reduced to tens of milliseconds, with potential for further improvements to meet customer demands in the future.

- Full Colorization: Most e-paper display technologies are primarily monochrome, and color e-paper has higher costs and technical challenges. Currently, color electrophoretic display e-paper can be achieved in two ways: one using a color filter over black and white e-paper, and the other using colored particles or dyes, with samples already produced. However, because it relies on reflected light for imaging, e-paper screens appear somewhat dim compared to the brightness and color accuracy of LCD screens. Thus, colorization is a revolutionary breakthrough for e-paper technology, with significant resources being devoted to research and development, promising the future availability of color e-paper displays.

- Durability: While e-paper is relatively durable, its performance may be impacted under extreme conditions (such as high temperatures and humidity). Unlike conventional readers who might not expect to roll up a book, the primary purpose of using flexible e-paper displays is not to be rollable but to be portable and impact-resistant. Flexible e-paper displays can opt for plastic substrates as backplanes. E-paper with plastic substrates is about 80% lighter than those made with glass materials and only about 0.3 mm thick, meeting the demands for lightweight, thin, and impact-resistant features. However, the biggest challenge for plastic substrates is their heat resistance and chemical stability, requiring ongoing improvements in substrate materials.

7. Applications of E-paper

- E-book Readers: E-paper is most famously used in e-book readers, such as Amazon’s Kindle. Due to its paper-like reading experience, e-paper allows users to read for long periods without significant eye fatigue.

- Billboards and Information Displays: Many businesses and public spaces are beginning to use e-paper for billboards and information display systems. E-paper’s clarity in sunlight and low energy consumption make it ideal for displaying information over extended periods.

- Smart Labels: In retail and logistics, e-paper labels (such as electronic shelf labels) are widely used. They can be updated in real-time with price and product information, reducing the costs associated with manual updates.

- Wearable Devices: Some smartwatches and fitness trackers have started incorporating e-paper display technology to enhance battery life and improve readability under various lighting conditions.

- Educational Devices: E-paper technology is gradually being adopted in the education sector, for example in electronic exam papers and learning tablets, offering a more flexible and environmentally friendly way of learning.