LCD modules typically have a backlight because they are transmissive, but e-paper is reflective and does not have a backlight, making it perfectly usable in daylight. However, there is also a need for e-paper applications at night, which has led to the introduction of a new term, “front light” (前光). This also includes discussions on touch technology and lamination techniques associated with E-paper displays.

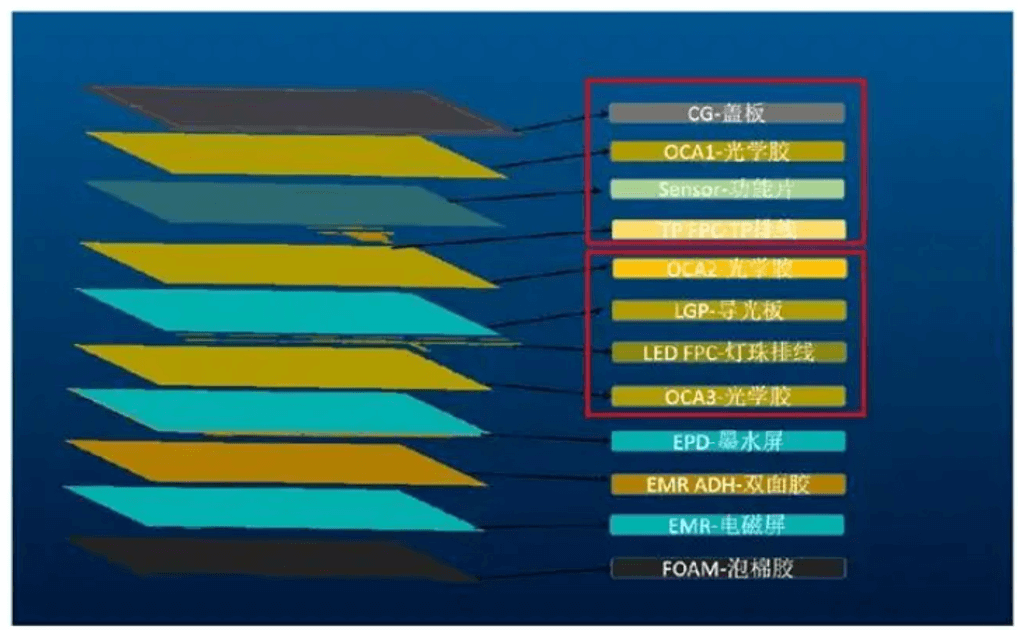

E-paper touch front light module structure

This is an overall diagram of the e-paper module. The upper red frame indicates the touch lamination, and the lower red frame shows the light guide component, followed by the EPD module and EMR. The touch lamination module consists of a cover plate, sensor, flexible circuit, and OCA. The front light component includes a light guide plate, OCA, and a flexible circuit containing beads. There are at least three layers of OCA, leading to a minimum of six lamination processes. The assembly plan is designed with one guide (dot pattern of the light guide plate), two types of lighting (cold and warm colors, or standard and high color gamut), three materials (materials for the light guide plate, sensor, and OCA), and at least six lamination processes.

Light guiding principle

This description refers to a schematic of a front light system, where light from a side-mounted source is manipulated using an input structure resembling gears and a dot pattern on the bottom. These structures refract or reflect the LED light, altering its direction to uniformly distribute it across the entire light guide plate. The illustration on the right shows this progression from a point (the light source) to a line (the light strip) to the entire surface of the light guide plate.

Color Saturation: Light Guide Plate Solution

Color e-paper modules, in comparison to monochrome ones, require light to pass through the RGB color filter twice, resulting in significant light loss, reduced brightness, and paler colors. To enhance brightness, changes were made to the dot patterns on the light guide plate. Smaller dots and adjusted angles increase effective light reflection. The angle of the dots was changed from 50° to 30°, which, through testing, increased light output by 10%.

Color Saturation: LED Bead Solution

Another approach to enhancing color saturation involves using LED lights. Specifically, using a blue LED chip that stimulates red and green phosphors to produce their respective colors. By enlarging the triangular areas where these interactions occur, the overall color gamut can be significantly broadened. In the images discussed, the left side exhibits some yellowish color distortion due to this effect. Despite all other aspects being the same, except for the type of LED beads, this results in markedly different visual outcomes.

The Impact of OCA Material

OCA material: The light guide plate has dots, typically concave. After lamination, the OCA fully immerses into the dots of the light guide plate, greatly impacting the optical matching and light guiding properties. The image on the left appears overall darker, which is also reflected in test data, whereas the data on the right shows overall brighter results. Just the difference in OCA materials can lead to this variation, hence the selection of different OCA materials is crucial for the corresponding product lamination.

The Impact of Sensor Material

Different sensor materials are currently used, mainly ITO Film and Metal Mesh. In terms of transparency, especially since color e-paper has higher demands for transparency, color e-paper generally prefers Metal Mesh. Both ITO Film and Metal Mesh work well with monochrome e-paper without any issues.

The Impact of Light Guide Materials

The material of the light guide plate significantly affects its performance because different materials influence the effectiveness of the dot patterns differently.

Should you have any questions about front-light, please contact our engineers.